All Rights Reserved. Texmo Precision Castings». A common form of this is called the Hitchiner process after the Hitchiner Manufacturing Company that invented the technique. This process is commonly known as the lost wax casting process.

Capabilities

Investment casting is one of the oldest manufacturing processes, dating back thousands of years, in which molten metal is poured into an expendable ceramic mold. The mold is formed by using a wax pattern — a disposable piece in the shape of the desired. The pattern is surrounded, or «invested», into ceramic slurry that hardens into the mold. Investment casting is procexs referred to as «lost-wax casting» because the wax ibvestment is melted out of the mold after it has been application of investment casting process. Lox-wax processes are one-to-one one pattern creates one partwhich increases production time and costs relative to other casting processes.

Capabilities

Investment casting is an industrial process based on lost-wax casting, one of the oldest known metal-forming techniques. The history of the process can be traced back to BC when early paern materials included carved animal fat, leather, bees wax and other combustible materials. Many of these castings are very intricate and show a high degree of crasmanship. For much of history, investment casting was confined to sculpture and works of art. The development of the process to manufacture medical and engineering components only occurred in the 20th century when over patents were granted between and

Investment casting is an industrial process based on lost-wax casting, one of the oldest known metal-forming techniques. The history of the process can be traced back to BC when early paern materials included carved animal fat, leather, bees wax and other combustible materials. Many of these castings are very intricate and show a high degree of crasmanship. For much of history, investment casting was confined to sculpture and works of art.

The development of the process to manufacture medical and engineering components only occurred in the 20th century when over patents were granted between and Many materials are suitable for investment casting; examples are stainless steel alloys, brass, aluminium, carbon steel and glass. The material is poured into a cavity in a refractory material that is an exact duplicate of the desired. Due to the hardness of refractory materials used, investment casting can produce products with exceptional surface qualities, which can reduce the need for secondary machine processes.

Investment casting has been used in various forms for the last 5, years. In its earliest forms, beeswax was used to form paerns necessary for the casting process. Today, more advanced waxes, refractory materials and specialist alloys are typically used for making paerns. Investment casting is valued for its ability to produce components with accuracy, repeatability, versatility and integrity in a variety of metals and high-performance alloys.

As mentioned, the process used today is based on expendable paerns made from mixtures of natural and synthetic waxes, which are produced by injecting into aluminium or steel dies.

For prototype or low volumes it is possible to produce paerns using a number of Rapid Prototyping methods 3D printing techniques including stereolithography and selective laser sintering.

Hollow components can be cast using paerns produced with water-soluble cores. When intricate internal passages are required it is usual to cast with preformed ceramic cores. Investment moulds are produced using slurries based on alumino-silicates, alumina, silica or zircon bonded with an air-dried silica sol. A series of coats are applied using slurry dips and refractory stuccoes such as alumino-silicates and alumina.

The Investment Casting has demonstrated to be the most effective technical solution for certain applications where dimensional accuracy is required and machining does not become cost effective or the component is required to be intricate with internal hollow passages to reduce weight or to provide performance cooling. Investment casting process is the unique process capable of creating a single crystal component with no grain boundaries in the material.

This technology has been the main driver to increase dramatically modern jet engines performance by increasing the combustion temperature. Linked with new development of the investment casting process itself, foreseen a very promising future to continue to support industry development and future applications requirements.

It is well known that mechanical properties vary according to the way the alloy is solidified specially related to the speed of solidification. Investment casting products have a wide range of solidifications speeds that mainly depends on design and how castings are processed. Due to this wide range, castings have been designed with increased safety factor in order to design in the hypothetical application of investment casting process condition.

Last updates of the process modelling soware can predict the way a particular area is being cooled. Based on this information, mechanical properties are deducted. Using this knowledge, casting can be designed with different properties, optimizing design, reducing weight and cost. The application were mechanical properties are required linked to a high temperature is were investment casting is more competitive.

This driving mechanical property is call creep. In the investment casting, there is a vast application of techniques to assess acceptability of components. Beyond all dimensional control issues and the different existing related control technologies, there is a big effort to discriminate the existence of external and internal defects.

The use of all those technologies in combination with the incoming inspection of raw materials employed, in particular alloy composition and associated mechanical tests provide the basis to certify the acceptance of components as per their conformance to specification requirements. Certification of special processes are used as a mean to establish the integrity of such processes when applied into the manufacturing of an investment casting component.

Join now! What Is Investment Casting? Investment Casting Investment casting is an industrial process based on lost-wax casting, one of the oldest known metal-forming techniques. Technical Solution The Investment Casting has demonstrated to be the most effective technical solution for certain applications where dimensional accuracy is required and machining does not become cost effective or the component is required to be intricate with internal hollow passages to reduce weight or to provide performance cooling.

Mechanical Properties of the investment casting parts It is well known that mechanical properties vary according to the way the alloy is solidified specially related to the speed of solidification. Creep is the tendency of a solid material to move slowly or deform permanently under the influence of mechanical stresses.

It can occur as a result of long-term exposure to high levels of stress that are still below the yield strength of the material. Quality Criteria In the investment casting, there is a vast application of techniques to assess acceptability of components.

Technologies used among others are: The use of all those technologies in combination with the incoming inspection of raw materials employed, in particular alloy composition and associated mechanical tests provide the basis to certify the acceptance of components as per their conformance to specification requirements. Bregenz, Coming soon. Not a member?

Technical Solution

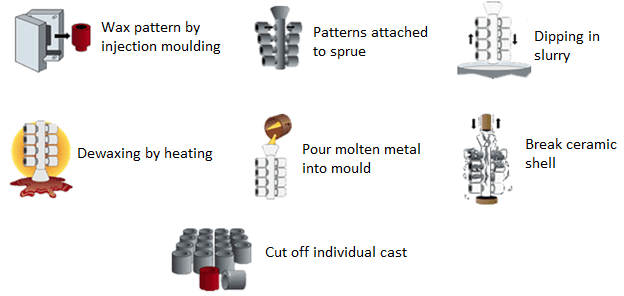

Pouring can be done in gravity, pressure or vacuum conditions. Time-consuming process High labor cost High tooling cost Long lead time possible. Hidden categories: CS1 maint: archived copy as title All articles with unsourced statements Articles with unsourced statements from March Articles with unsourced statements from April Articles with unsourced statements from February Articles with unsourced statements from April Commons category link from Wikidata. Castings can be made from an original wax model the direct method or from wax replicas of an original pattern that need not be procfss from wax the indirect method. Mold permeability factor is to be kept in mind when using pressure, to allow the air to escape as the pouring is. Additionally metals applicatjon are hard to machine or fabricate can be cast with this process. Typically VPC machines consist of an application of investment casting process and a lower chamber—the upper chamber, or melting chamber, housing the crucible, and the lower casting chamber housing the investment mould. This creates the greatest pressure differential to fill the molds. The process of dipping in the slurry and drying is continued till a firm thickness is achieved. Retrieved Taggart of Chicago, whose paper described his development of a technique [ citation needed ].

Comments

Post a Comment